X-rings - for universal use

X-rings are double-acting, circular sealing elements with an X-shaped square cross section. X-rings are relatively similar to O-rings in terms of handling and use, but they offer some advantages in dynamic applications.

Applications

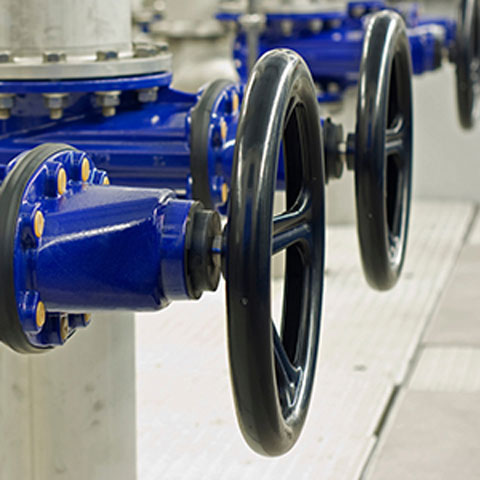

Versatile as a dynamic seal at low and medium speeds and as a static seal

- Dynamic seal for reciprocating movements on pistons, rods, etc.

- Dynamic seal for pivoting, rotating or helically moving shafts, spindles, etc.

- Static seal, radial or axial for flanges, covers, bushings, pipes, etc.

Special properties

- They exhibit no tendency to twist during reciprocating movements and installation thanks to the special four-lip profile

- Low friction

- Recess between the sealing lips serves as a lubricant reservoir, lower breakaway forces and static friction

- Unlike in O-rings, the flash is between the sealing lips and has no negative effect on the sealing behaviour

- Optimised sealing behaviour in dynamic applications thanks to the special distribution of the contact pressure over the profile

Materials

Standard materials

NBR 70 black

FKM 70 black

Special materials

EPDM, VMQ, FFKM,

and others on request

Dimensions

International Standard AS 568

French Standard (QR...)

Usage parameters

NBR 70 black

Temperature: -30°C to +100°C

Pressure: Static up to 5 MPa

With support ring up to 40 MPa

Dynamic, reciprocating up to 5 MPa

With support ring up to 30 MPa

Rotating up to 5 MPa

With support ring up to 15 MPa

Speed: ≤ 0.5 m/s reciprocating

≤ 2 m/s rotating, for short periods

(Special design required)

Media / good resistance to:

mineral oil-based oils and greases, aliphatic hydrocarbons, hydraulic oils H, H-L, H-LP, hydraulic fluids HFA, HFB, HFC, water up to 80°C

FKM 70 black

Temperature: -15°C to +200°C

Pressure: Static up to 5 MPa (50 bar),

With support ring up to 40 MPa

Dynamic, reciprocating up to 5 MPa (50 bar)

With support ring up to 30 MPa

Rotating up to 5 MPa

With support ring up to 15 MPa

Speed: ≤ 0.5 m/s reciprocating

≤ 2 m/s rotating, for short periods

(Special design required)

Media / good resistance to:

mineral oil-based oils and greases, synthetic oils and greases, aliphatic, aromatic and chlorinated hydrocarbons, hydraulic fluids HFD, fuels, non-polar solvents, ozone, weather, ageing, UV radiation, water up to 80°C

Download our brochure as PDF

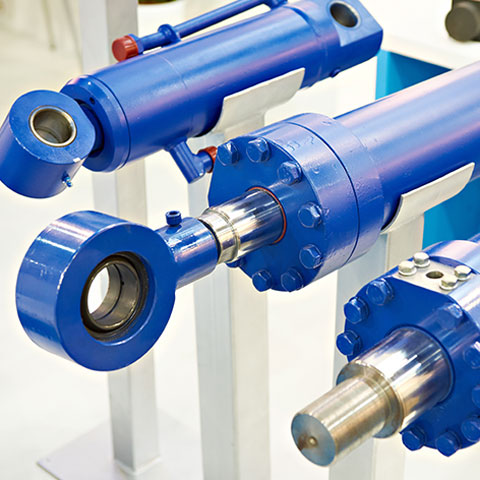

NEW in stock RP-78!

When it comes to harsh applications, you're in the right place with the rod and the piston seal RP-78 (loaded U-CUP).

Available directly from stock at anyseals! We have over 400 sizes In stock with pricing!

Rod and Piston Seals